When you're building a new home, understanding the budget is critical, and one of the first major expenses you'll encounter is framing. As a general guide, you can expect the total cost of framing a house to fall between $15 and $30 per square foot, which includes both materials and the labor to put it all together.

For a standard 2,000-square-foot house, this means the framing portion of your budget will likely be somewhere between $30,000 and $60,000. This is a significant piece of your total construction cost, so getting this estimate right is crucial for planning your finances.

Understanding the Basics of House Framing Costs

Think of framing as building the skeleton of your new home. It’s the essential structure that supports everything else—walls, floors, and the roof—and gives the house its shape. Because it’s so fundamental, understanding the cost of framing a house is a key first step for anyone building from the ground up.

Framing isn't a minor expense. It often accounts for 15% to 20% of your entire project budget. Nailing this number down early helps you create a realistic financial plan from the very beginning.

House Framing Cost at a Glance

To give you a quick reference, here’s a look at some common framing cost scenarios for different home sizes.

| Metric | Average Cost Range |

|---|---|

| Cost Per Square Foot | $15 – $30 |

| 1,500 sq. ft. Home | $22,500 – $45,000 |

| 2,000 sq. ft. Home | $30,000 – $60,000 |

| 2,500 sq. ft. Home | $37,500 – $75,000 |

These figures are a great starting point, but keep in mind that several factors can push your final costs toward the lower or higher end of these ranges.

Why Framing Costs Vary

You can't just multiply your home's square footage by a flat rate and call it a day. Several key elements will influence your final framing bill.

- House Size and Stories: This one’s straightforward—a larger home requires more materials and more labor. A two-story house will also cost more to frame than a single-story home of the same square footage due to the added complexity, engineering, and safety needs.

- Architectural Design: A simple, rectangular house is the most affordable to frame. As you add more corners, complex rooflines, vaulted ceilings, or custom angles, the labor and material waste increase, driving up the price.

- Material Choice: The price of lumber and steel changes constantly based on supply chains and market demand. A sudden spike in lumber prices can directly impact your budget.

- Local Labor Rates: This is a big variable. Labor costs can differ dramatically from one region to another. Skilled framers in high-cost-of-living urban areas will charge much higher wages than those in rural markets.

Nationwide, the average cost to frame a house lands somewhere between $30,000 and $80,000, depending on the project's size and complexity. This makes framing a substantial part of the total building cost, which itself averages between $125 and $300 per square foot across the country.

Getting a firm grasp on these factors is the first step. For a deeper dive into the entire budgeting process for a project, check out our detailed guide on how to estimate renovation costs.

The Biggest Factors Driving Your Framing Budget

Ever wonder why framing a sleek, modern rectangle of a house costs so much less than a sprawling custom home, even if they have the same square footage? The answer is a handful of key factors that can dramatically swing your budget.

Getting a handle on these drivers is the first step toward controlling your final framing cost. Think of it like paving a road: a simple, straight shot is always cheaper and faster than a winding mountain pass with tons of sharp turns. The same logic applies to your home’s skeleton.

House Size and Height

The most obvious factor is the sheer size of your home. A larger footprint simply requires more lumber, more fasteners, and more hours from the crew. It's the most direct relationship you'll see—the bigger the house, the higher the framing bill.

But it's not just about the footprint. The number of stories plays a massive role, too. A two-story, 2,000-square-foot house will cost more to frame than a single-story home with the exact same square footage. Why? Because multi-story structures demand more engineering for support, more complex floor joist systems, and increased safety measures for the crew working at heights.

Architectural Complexity

This is where your budget can really start to climb. A simple rectangular house is a framer's dream. It has four corners and a straightforward roofline, which means it’s efficient to build and creates minimal material waste.

Now, imagine a custom design loaded with multiple gables, dormers, vaulted ceilings, bay windows, and tons of corners.

Each unique angle and architectural flourish adds a layer of complexity. This translates directly into more intricate cuts, extra support structures, and way more time for your framing crew to get it right. More complexity equals more labor, which is a huge chunk of your final bill.

Bottom line: simple, clean designs are always more budget-friendly. Complex, custom plans demand a higher level of skill and more materials to execute safely and correctly.

Material Choices and Market Prices

The "sticks" themselves are a major variable. While wood is the go-to choice, the type and grade of lumber you use matter. But even more important is the fact that lumber prices are notoriously volatile. They can swing wildly due to global supply chain hiccups, trade policies, and even natural events like wildfires.

A sudden spike in lumber prices can add thousands of dollars to your framing quote almost overnight. This is exactly why getting a quote with a clear expiration date is critical. It protects both you and your builder from getting burned by unexpected market swings.

Labor Rates and Location

Where you build has a massive impact on your costs. Skilled labor is a huge piece of the framing budget, often making up 40% to 60% of the total. And labor rates vary dramatically by region. A framing crew in a major metro area like San Francisco will have a much higher hourly rate than a crew in a rural town.

Your location also affects other costs, like permits and site prep. Clearing and grading a flat, easily accessible lot is far cheaper than dealing with a sloped or rocky one that requires extensive excavation. Before a single piece of lumber is cut, the land has to be ready. For a closer look at those initial expenses, our guide on the costs of demolition can give you some valuable context.

Decoding Your Framing Quote: Materials vs. Labor

When you get a framing quote from a builder, it’s tempting to just look at the final number. But if you want to control your budget, it's helpful to understand what’s behind that total. Every framing estimate boils down to two core components: materials and labor.

Think of it like buying a custom piece of furniture. You have the cost of the wood and screws (the raw ingredients), and then you have the cost of the craftsman's time and skill to build it. It's the same with framing, and the split between the two isn't always 50/50.

The Material and Labor Breakdown

More often than not, labor costs make up 40% to 60% of the total framing bill. This piece of the pie covers the wages for the skilled carpenters who show up every day to measure, cut, and assemble the structure of your house.

That percentage can easily climb higher if your home design has complex architectural features like intricate rooflines, curved walls, or vaulted ceilings. These require more time, precision, and expertise to get right.

Materials, of course, account for the other 40% to 60%. This includes every piece of lumber, steel beam, sheathing, and all the nails and screws needed to build your home's skeleton. This part of your budget is most affected by market price swings.

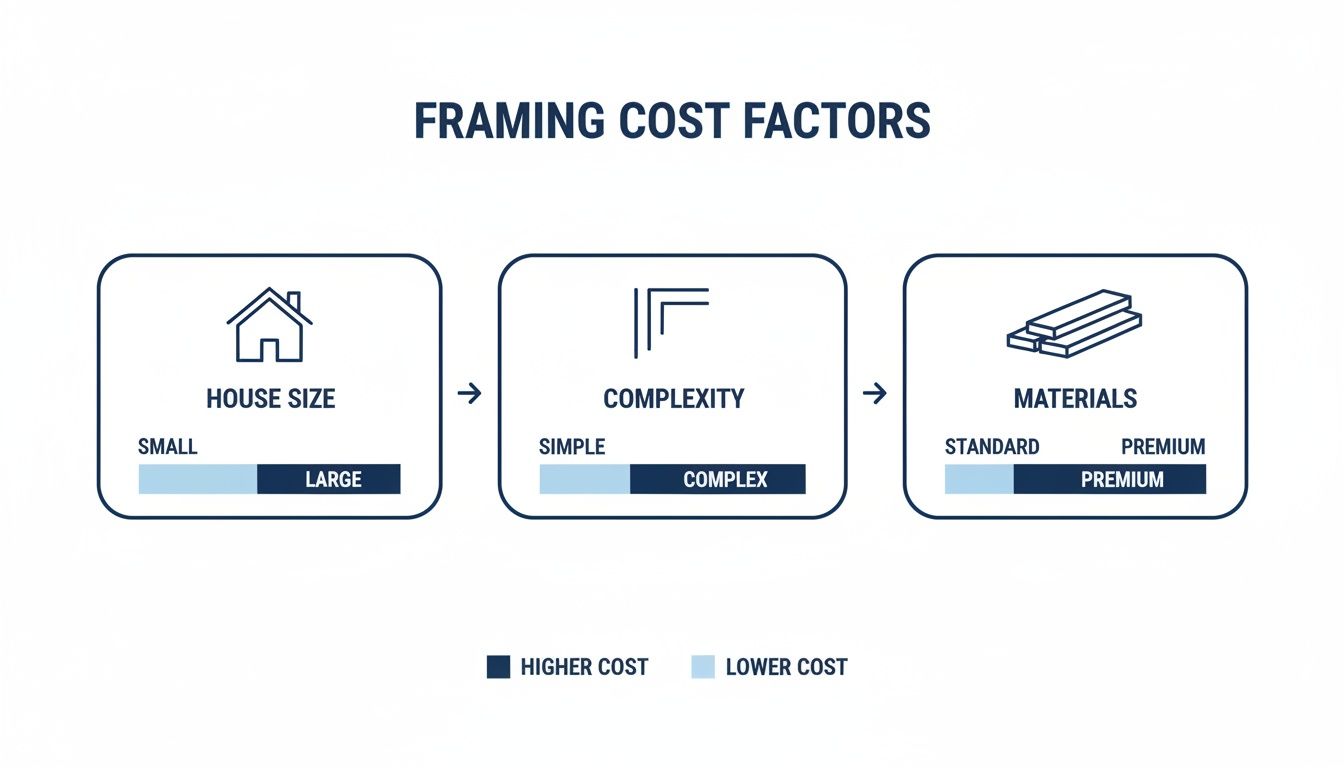

This diagram helps visualize how the core factors—size, complexity, and materials—drive the final cost.

As you can see, a larger and more complex home doesn't just need more materials; it demands significantly more labor, compounding the impact on your final quote.

Why Material Costs Fluctuate So Much

Lumber prices are notoriously volatile. They can change quickly based on everything from sawmill capacity and supply chain issues to global trade policies. This volatility is a major reason why most framing quotes come with an expiration date.

A contractor can't lock in material prices for long. For a real-time pulse on the market, you can check resources like TimberCloud's pricing information to see how these costs are trending.

This isn't just a short-term issue. Historically, the cost of construction has been taking up a bigger slice of a new home's price. One recent study showed that construction costs hit 64.4% of the average new home's price tag, a big jump from 60.8% just a few years prior and the highest it's been in over two decades.

Key Takeaway: Don't be surprised if your labor quote is higher than your material quote. An intricate design requires more skilled work, driving up labor's share, while a sudden spike in lumber prices can just as easily flip that balance.

Understanding this dynamic is crucial for anyone building a home. Accurately projecting these costs is fundamental to your success. You can dive deeper into managing these variables in our guide on estimating repair costs, where the principles apply directly to budgeting for new construction.

Armed with this knowledge, you can review any contractor's quote with confidence, knowing exactly where every dollar is supposed to go.

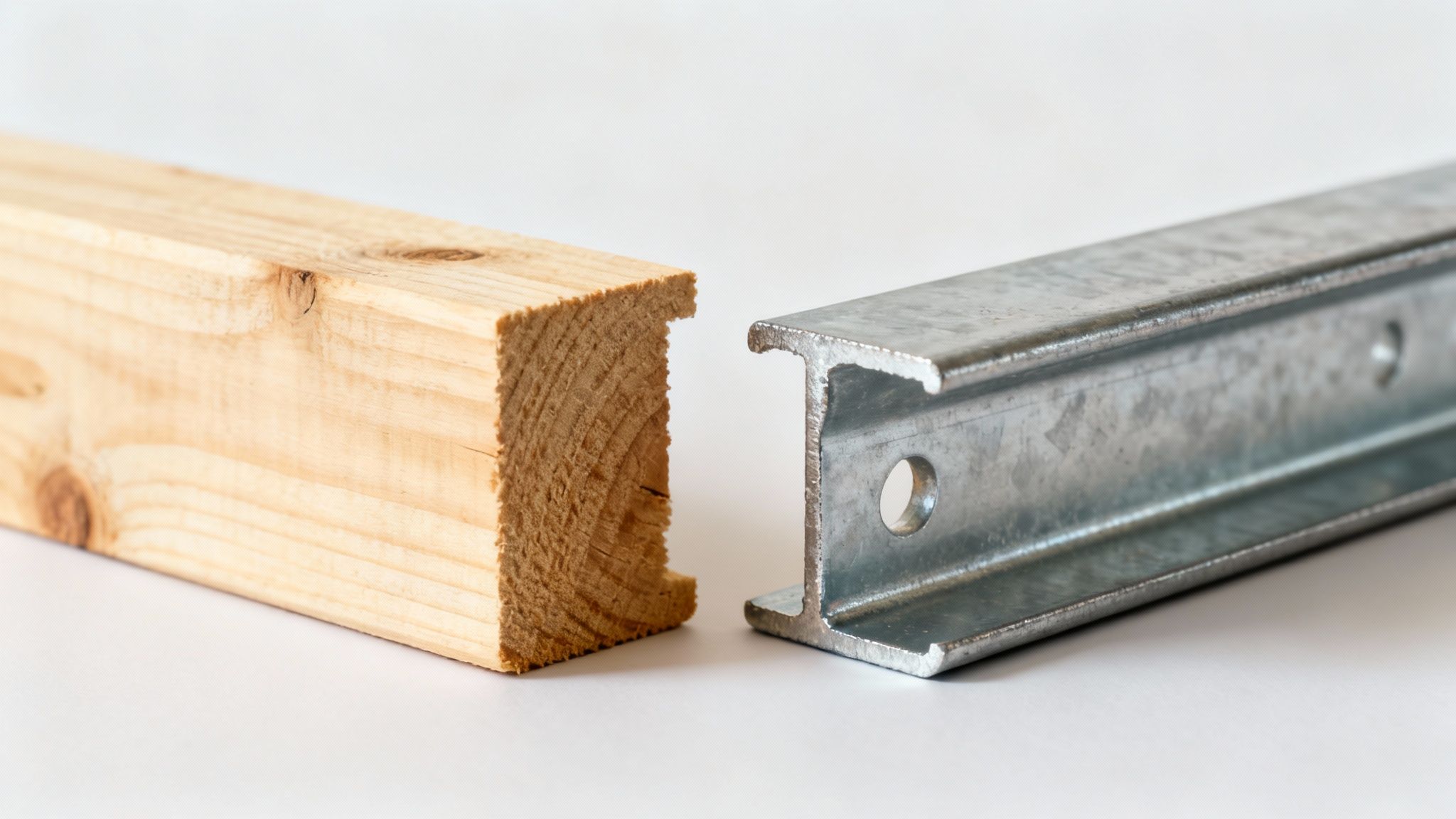

Choosing Your Frame: Wood vs. Steel Costs and Benefits

One of the first big decisions you'll make that directly impacts the cost of framing a house is the material you choose for its skeleton. The classic debate is wood versus steel. This choice affects not just the upfront price, but also your labor costs and the home's long-term resilience.

The Case for Traditional Wood Framing

There’s a reason wood is the most common framing material in the United States. It's what most residential builders know best, which means you’ll have a larger pool of contractors to choose from and more competitive bids. On paper, the material itself is almost always cheaper than steel.

The big catch with wood, however, is price volatility. Lumber costs can swing wildly based on supply chain issues, market demand, or even trade policies. Wood is also vulnerable to things like moisture, termites, and fire, which means you'll need to factor in preventative treatments and future maintenance.

The Advantages of Modern Steel Framing

Steel framing is a powerful alternative, especially if strength and durability are your top priorities. Steel studs are manufactured to be perfectly straight, so they won't warp, twist, or shrink as the house settles. This means straighter walls and fewer cosmetic issues like nail pops down the line.

Better yet, steel is naturally resistant to fire, termites, and rot. This can translate into lower homeowner's insurance premiums and serious peace of mind. While steel materials typically cost 15% to 30% more than wood, its lighter weight can sometimes reduce foundation requirements and speed up assembly, which might save you money on labor.

A key thing to remember with steel is finding a crew that's experienced with it. While it's standard in commercial construction, not all residential framers are steel experts. Finding a specialized crew could impact your labor costs and project timeline.

Wood vs. Steel Framing: A Head-to-Head Comparison

To make the decision a little easier, here’s a straightforward breakdown of how these two materials stack up against each other.

| Feature | Wood Framing | Steel Framing |

|---|---|---|

| Upfront Material Cost | Generally lower, but prices are highly volatile. | Typically 15-30% higher than wood, but prices are more stable. |

| Durability | Prone to rot, termites, and fire without treatment. Can warp or shrink. | Resistant to fire, insects, and moisture. Will not warp or shrink. |

| Labor & Installation | Familiar to most residential crews, making labor easy to find. | May require specialized labor, which can potentially increase costs. |

| Weight | Heavier, which may require more substantial foundation and support. | Lighter than wood, which can simplify engineering and foundation needs. |

| Environmental Impact | A renewable resource, but processing can be energy-intensive. | Highly recyclable, but its production is also energy-intensive. |

In the end, choosing between wood and steel framing is a balancing act. You have to weigh the upfront material costs against long-term performance, maintenance, and the specific goals of your project.

How Global Events Affect Your Local Building Costs

It might seem disconnected—thinking events happening thousands of miles away could hike up your local framing quote—but that’s the reality of today’s construction market. The cost of framing a house is deeply tied to the global economy. Your home’s skeleton is built with commodities like lumber and steel, and their prices can be surprisingly volatile.

Think of it like the price of gas. International supply snags or new trade deals can make the numbers at your local pump jump overnight. Lumber and steel behave in much the same way.

The Ripple Effect of Global Economics

When international shipping lanes get congested or a major lumber-producing country is hit with wildfires, the supply of materials tightens. That scarcity drives up prices for everyone, right down to your local building supplier. Naturally, the quote your builder gives you has to reflect those higher costs.

Inflation is another big player. As the cost of everything from energy to transportation climbs around the world, so does the cost of producing and shipping building materials. Those increases eventually get passed down to you, the home buyer.

This is exactly why building a 10-15% contingency fund into your budget is non-negotiable. It acts as a financial shock absorber for price swings you can't control, keeping your project on track even when material costs suddenly spike.

Understanding this bigger picture helps you see why construction quotes aren't set in stone. Global construction cost inflation remains a powerful force. In places like the US and UK, for example, construction cost inflation is expected to hover around 3.5–3.8%. On top of that, trade policies like tariffs can threaten to push prices for framing materials even higher. You can dig deeper into these global construction cost trends to see just how interconnected your project is with the world economy.

Smart Ways to Save Money on House Framing

Managing the cost of framing a house is a balancing act. You want to save money, but you can't compromise on structural integrity. The secret isn't just spending less—it's spending smarter.

The single most effective way to control framing costs happens long before construction begins: the design phase. A simple architectural footprint, like a classic rectangle or L-shape, is dramatically cheaper to frame than a complex design with dozens of corners and intricate rooflines. Every extra angle adds both labor time and material waste.

Optimize Your Material and Bidding Strategy

Another huge money-saver is designing around standard material dimensions. Talk to your architect or builder about using standard lengths of lumber and full sheets of plywood whenever possible. This simple strategy minimizes cuts, which reduces labor hours and the pile of expensive scrap wood left at the end of the day.

When you're ready to hire, never settle for the first quote you get. It is essential to get detailed bids from at least three different, reputable framing contractors. Getting them to compete for your business is the only way to know you’re getting a fair market price.

Make sure every bid is an "apples-to-apples" comparison. It should detail the exact same scope of work and quality of materials. A bid that looks too good to be true probably is—it might mean they’re cutting corners on insurance, safety, or using lower-grade lumber that could cost you more in the long run.

Finally, think about timing. If your project schedule has flexibility, try to schedule your framing during the off-season (late fall or winter in most colder climates). With contractors being less busy, you’ll often find more competitive labor rates.

Practical Steps for a Leaner Budget

Here are a few actionable steps to discuss with your builder before you get started:

- Stick to a Simple Footprint: Keep the exterior walls as straight as possible and opt for a straightforward roof design. Complexity is the enemy of your budget.

- Get Multiple Bids: Always compare detailed quotes from several insured and licensed contractors. This ensures you're paying a fair price.

- Time Your Build: If you can, avoid the peak construction season. You might lock in better labor rates when demand is lower.

- Monitor Expenses Diligently: To truly keep costs in check, you have to track job and project costs effectively from start to finish. This helps you spot budget overages before they spiral out of control.

Frequently Asked Questions About Framing Costs

Navigating the costs of new construction can feel overwhelming. Here are answers to a few common questions home buyers have about framing.

How much of my total construction budget should go to framing?

As a solid rule of thumb, you should plan for the framing to be 15% to 20% of your total construction budget. For example, on a home with a total construction cost of $400,000, you would budget between $60,000 and $80,000 for framing. A simpler home design will be closer to 15%, while a complex, custom home will be closer to 20% or more.

Can I save money by framing the house myself?

While it may seem tempting to save on labor by doing it yourself, framing is a highly skilled job that forms the structural backbone of your home. A small mistake can compromise safety, fail inspections, and lead to repairs that cost far more than the labor you were trying to save. For the vast majority of people, hiring a licensed and insured professional framing crew is the safest and most reliable investment.

Does my foundation choice affect framing costs?

Yes, it does. While foundation and framing are separate costs, they are directly connected. A simple, flat concrete slab provides the easiest base for framers to work on. More complex foundations, like a walk-out basement on a sloped lot, require more detailed work to build the first-floor system correctly. This added complexity increases labor time and, therefore, your overall framing cost.

Ready to stop guessing and start analyzing? Flip Smart gives you the tools to calculate renovation costs, including framing, and determine a property's true potential in seconds. Analyze your next property with confidence.